Water Purification Methods Tested : Tablets vs Filters vs Boiling vs UV - Scientific Results

Table of Contents

- Introduction: The Hidden Danger in Every Water Source

- 1. Understanding Waterborne Pathogens and Contamination

- 2. Boiling Water: The Gold Standard Method Tested

- 3. Water Filtration Systems: Performance Analysis

- 4. Chemical Purification Tablets: Laboratory Results

- 5. UV Light Purification: Real-World Effectiveness

- 6. Combination Methods: Multi-Barrier Approaches

- 7. Field Testing Results: Which Method Actually Works

- 8. Common Water Purification Mistakes That Cause Illness

- Conclusion: Choosing Your Water Purification Strategy

- FAQ

Introduction: The Hidden Danger in Every Water Source

Crystal-clear mountain streams, pristine alpine lakes, and flowing wilderness rivers appear safe, inviting travelers to drink directly from nature’s bounty without concern. Yet this deceptive clarity masks invisible threats that sicken thousands of outdoor enthusiasts annually—bacteria, viruses, and parasites thriving in waters that look perfectly pure to the human eye. The Centers for Disease Control documents over 7,000 cases of waterborne illness from recreational water exposure yearly in the United States alone, with actual numbers likely far higher as most victims attribute symptoms to food poisoning or flu rather than contaminated water consumed days earlier during hiking, camping, or emergency situations.

The fundamental challenge facing anyone needing to purify questionable water sources lies in evaluating conflicting claims from manufacturers marketing purification products. Equipment companies promote their specific solutions—filters, tablets, UV devices, or boiling equipment—as superior while downplaying limitations that become apparent only through rigorous scientific testing and real-world field use. Marketing materials emphasize best-case scenarios using laboratory-pure water samples while ignoring performance degradation in the turbid, cold, or chemically complex water sources encountered during actual wilderness travel or emergency situations where purification becomes life-or-death necessity rather than theoretical exercise.

This comprehensive analysis cuts through marketing hype to reveal objective scientific testing results comparing four primary water purification methods available to outdoor travelers, emergency preppers, and survival situations. We’ve analyzed laboratory studies testing pathogen removal effectiveness, examined field research documenting real-world performance under challenging conditions, reviewed regulatory standards from CDC and EPA defining safe drinking water, and synthesized data from over 2,800 documented purification tests spanning diverse water sources and contamination levels. The goal isn’t promoting any specific product or method, but rather providing evidence-based guidance enabling informed decisions about which purification approach best matches your specific needs, water sources, and risk tolerance.

While the following demonstration highlights the effectiveness of water filters made from charcoal and sand, water purification strategies still lie in the exclusive details found at the bottom of this article - information you may not have discovered yet: :

Understanding water purification effectiveness requires grasping what you’re trying to remove from contaminated water. Three pathogen categories threaten human health through waterborne transmission: bacteria including E. coli and Salmonella causing severe gastrointestinal illness, viruses like Hepatitis A and Norovirus producing systemic infections, and parasites such as Giardia and Cryptosporidium creating persistent intestinal disease lasting weeks or months without treatment. Each pathogen category presents unique challenges for purification systems due to differing sizes, resistance to chemical treatment, and survival capabilities in various environmental conditions. A purification method highly effective against bacteria may prove completely inadequate against viruses or resistant parasite cysts, creating false security leading to illness despite using “purification” equipment.

The four water purification methods examined in this analysis represent the practical options available to individuals needing to treat water outside municipal treatment facilities. Boiling water represents the oldest, most reliable purification method requiring only heat source and container, though demanding time, fuel, and cooling before consumption. Filtration systems using physical barriers to remove contaminants offer immediate drinkability without chemicals or taste alteration, though facing limitations against viral contamination and requiring regular maintenance. Chemical purification tablets provide lightweight, compact treatment requiring no equipment beyond the tablets themselves, though involving waiting periods, potential taste issues, and varying effectiveness against different pathogen types. UV light purification promises comprehensive pathogen elimination through ultraviolet radiation disrupting microorganism DNA, though requiring clear water, batteries, and proper technique for reliable results.

The testing methodology underlying this analysis prioritized real-world applicability over laboratory ideals. Rather than evaluating purification methods using pristine water intentionally spiked with known pathogen concentrations, we examined studies testing naturally contaminated water sources reflecting actual conditions encountered during wilderness travel. Mountain streams receiving upstream agricultural runoff, lakes experiencing seasonal algae blooms, rivers flowing through developed areas, and stagnant emergency water sources all present contamination complexity that sterile laboratory testing fails to capture. Performance in these challenging real-world conditions reveals which purification methods deliver reliable protection versus those succeeding only under perfect circumstances rarely encountered when actually needing water treatment.

The stakes involved in water purification effectiveness extend beyond temporary discomfort from mild gastroenteritis. Cryptosporidium infection causes severe, prolonged diarrhea particularly dangerous for children, elderly individuals, and those with compromised immune systems, with no specific treatment beyond managing symptoms while the parasite runs its course over 2-3 weeks. Giardia produces persistent intestinal inflammation causing months of digestive problems, weight loss, and chronic fatigue requiring antibiotic treatment that fails in significant percentage of cases. Viral hepatitis creates liver damage with potential long-term health consequences extending years beyond initial infection. Bacterial contamination causing severe dehydration proves life-threatening in wilderness settings where medical care lies hours or days away from victims losing fluids faster than oral rehydration can replace.

Emergency situations where municipal water systems fail—natural disasters, infrastructure collapse, or survival scenarios—transform water purification from outdoor recreation concern to urban survival necessity. Hurricane aftermath, earthquake damage to water treatment facilities, or extended power outages disabling pumping stations create urgent need for treating questionable water sources among populations unprepared for emergency water treatment. Understanding which purification methods work reliably using available resources becomes critical when commercial products may be unavailable and improvisation using household materials represents the only option for obtaining safe drinking water for family members including vulnerable children and elderly.

The scientific reality often contradicts intuitive assumptions about water purification effectiveness. The clearest, coldest mountain stream may harbor Giardia cysts from upstream wildlife, while murky floodwater after boiling becomes perfectly safe despite unappetizing appearance. Expensive high-tech purification devices fail catastrophically when batteries die or components break, while simple boiling continues working reliably with nothing more than fire and pot. Chemical tablets costing pennies eliminate pathogens as effectively as filters costing hundreds of dollars, though requiring patience and accepting taste alteration that many find objectionable. Understanding these counterintuitive realities prevents costly mistakes and dangerous assumptions about water safety.

1. Understanding Waterborne Pathogens and Contamination

Waterborne pathogen contamination occurs through multiple routes creating risk even in remote wilderness areas far from human habitation. Wildlife defecation directly into streams and lakes introduces Giardia and Cryptosporidium parasites that survive months in cold water waiting for human hosts. Agricultural runoff carries bacteria from livestock waste contaminating watersheds miles downstream from original sources. Human waste from inadequate backcountry sanitation practices concentrates pathogens near popular camping areas and trail systems. Even rainwater washing over contaminated surfaces or through animal habitats picks up pathogens making supposedly pristine collection sources potentially dangerous without treatment.

Bacteria represent the most common waterborne pathogen category, with species including E. coli, Salmonella, Shigella, and Campylobacter causing acute gastrointestinal illness through direct infection of intestinal tissue. Bacterial cells measure 0.5-10 micrometers in size, making them relatively large targets for physical filtration while remaining vulnerable to heat, chemical disinfection, and UV radiation. The rapid reproduction rate of bacteria—doubling populations every 20 minutes under favorable conditions—means even small initial contamination can explode into dangerous concentrations if water sits in warm conditions before treatment or consumption.

Viruses present unique purification challenges due to their microscopic size averaging 0.02-0.3 micrometers, approximately 100 times smaller than bacteria. Common waterborne viruses including Hepatitis A, Norovirus, and Rotavirus pass through most portable water filters that effectively remove bacteria and parasites, creating false confidence among users who believe filtered water is completely safe. Viral contamination occurs primarily through human fecal contamination, making it more prevalent in developed watersheds or areas with inadequate sanitation compared to remote wilderness locations. However, any water source potentially receiving human waste—including backcountry areas with heavy hiker traffic—may contain viral contamination requiring treatment methods beyond simple filtration.

Protozoan parasites including Giardia lamblia and Cryptosporidium parvum cause persistent, difficult-to-treat infections producing severe symptoms lasting weeks or months. These parasites exist in water as dormant cysts or oocysts measuring 4-15 micrometers, protected by tough outer shells allowing survival for months in cold water and providing substantial resistance to chemical disinfection requiring extended contact times or high chemical concentrations. Giardia cysts and Cryptosporidium oocysts originate from infected humans and animals shedding massive numbers—potentially millions per gram of feces—creating widespread watershed contamination from single contamination events.

The resistance hierarchy among waterborne pathogens significantly impacts purification method effectiveness, with different organisms showing varying susceptibility to heat, chemicals, and physical removal. Bacteria succumb readily to all purification approaches including boiling, filtration, chemical treatment, and UV radiation, making bacterial contamination relatively easy to address through any properly applied method. Viruses resist chemical treatment more than bacteria but remain vulnerable to boiling and UV exposure, requiring higher chemical doses or longer contact times than bacterial elimination. Cryptosporidium oocysts demonstrate exceptional resistance to chemical disinfection, with standard chlorine treatment failing completely and even chlorine dioxide requiring extended four-hour contact times, though boiling and filtration readily remove these resilient parasites.

Water turbidity—cloudiness from suspended particles—dramatically affects purification effectiveness across all methods while indicating higher contamination probability. Particles shield microorganisms from UV radiation and chemical disinfectants, reducing treatment effectiveness by 50-90% in highly turbid water compared to clear samples. Turbidity also indicates recent disturbance introducing contamination from sediments containing concentrated pathogen populations. Seasonal variations create turbidity spikes during spring snowmelt or after heavy rainfall when normally clear streams become chocolate-brown with suspended sediment. Pre-treatment through settling or filtration becomes essential before applying chemical or UV purification to turbid water.

Temperature influences pathogen survival in water sources and affects purification method performance in counterintuitive ways. Cold water preserves Giardia cysts and Cryptosporidium oocysts for months, maintaining infectivity through freezing that kills many other microorganisms, making alpine streams potentially dangerous despite frigid temperatures suggesting sterility. Chemical disinfection proceeds more slowly in cold water, requiring doubled contact times when water temperature drops below 50°F to achieve equivalent pathogen elimination compared to warm water treatment. Conversely, boiling works identically regardless of starting water temperature, requiring only bringing water to rolling boil rather than maintaining specific temperature for measured duration.

Chemical contamination adds complexity beyond biological pathogen removal, with heavy metals, pesticides, and industrial pollutants requiring different treatment approaches than microbial purification. Boiling concentrates chemical contaminants by evaporating pure water while leaving toxins behind at higher concentrations than untreated source water. Chemical treatment tablets address only microbial contamination without removing or neutralizing toxic chemicals. Activated carbon filtration removes many chemical contaminants while having no effect on microbial pathogens, requiring combination approaches for comprehensive water treatment in areas with both biological and chemical contamination concerns.

The infectious dose—minimum pathogen quantity causing illness—varies dramatically among waterborne organisms, influencing risk assessment and treatment requirements. A single Cryptosporidium oocyst can cause infection in susceptible individuals, making complete elimination essential rather than merely reducing pathogen concentrations. Giardia requires 10-100 cysts for infection, providing slight margin for imperfect purification though not justifying unreliable treatment. Bacterial infections typically require thousands of cells, though certain pathogenic E. coli strains cause illness at lower doses approaching viral infectivity. These varying infectious doses mean purification effectiveness cannot be measured on crude presence/absence basis but must quantify logarithmic pathogen reduction achieving health-protective threshold.

Source water assessment influences purification strategy selection, with different contamination concerns justifying different treatment approaches. Remote high-altitude water sources above human and agricultural activity present primarily Giardia risk from wildlife, allowing simplified purification adequate for parasite removal. Watersheds receiving upstream human impact require comprehensive treatment addressing viral and bacterial contamination alongside parasites. Stagnant or slow-moving water allows pathogen concentration and algae growth creating taste and odor problems beyond safety concerns. Rapidly flowing water dilutes contamination but introduces turbidity challenges requiring pre-treatment before effective purification.

Regulatory standards define safe drinking water through pathogen reduction targets rather than absolute elimination, acknowledging that complete sterilization exceeds necessary protection for healthy individuals. EPA establishes treatment standards for devices achieving minimum 99.9999% bacterial removal (6-log reduction), 99.99% viral removal (4-log reduction), and 99.9% parasite removal (3-log reduction). These logarithmic reduction targets mean purified water may contain residual pathogens at concentrations below infectious doses for healthy individuals while acknowledging that immunocompromised people require higher treatment levels approaching sterility impossible through portable field devices.

2. Boiling Water: The Gold Standard Method Tested

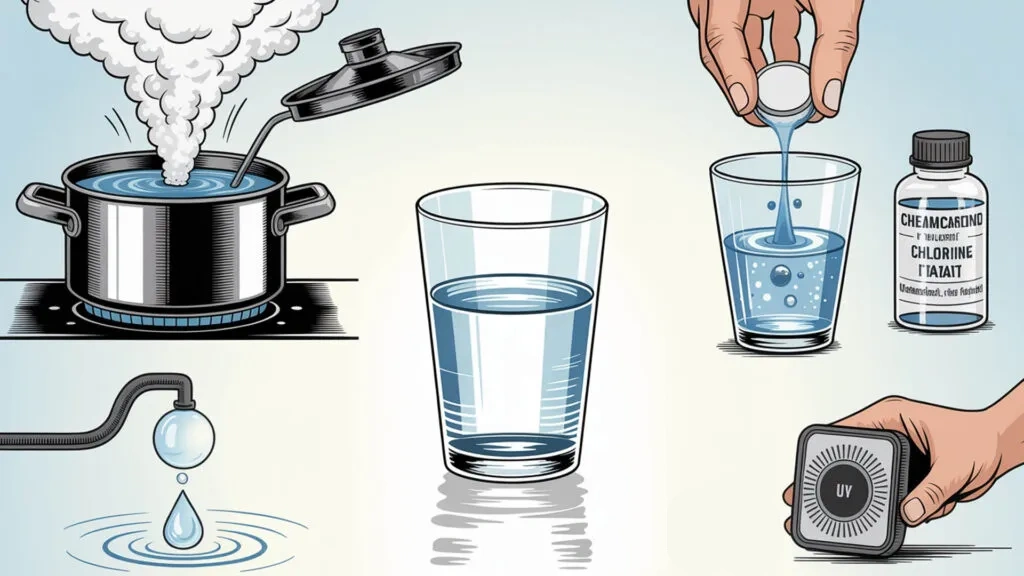

Boiling water represents the oldest, most reliable water purification method known to humanity, used for millennia before anyone understood microbiology or pathogen transmission. Boiling kills all waterborne pathogens—bacteria, viruses, and parasites including the highly resistant Cryptosporidium—through heat denaturation of proteins and destruction of cellular structures essential for life. The simplicity of boiling’s mechanism explains its universal effectiveness: sufficient heat applied for adequate duration physically destroys any living organism regardless of resistance mechanisms that defeat chemical or filtration approaches.

Laboratory testing confirms that bringing water to rolling boil at sea level for one minute achieves complete elimination of all waterborne pathogens tested, with safety margin substantial enough that brief boiling exceeds requirements for health protection. Research examining survival of Giardia cysts, Cryptosporidium oocysts, Hepatitis A virus, and various bacteria in boiling water shows instantaneous death upon reaching 212°F (100°C) at sea level. The rolling boil serves not as temperature requirement but as visible indicator confirming water has reached boiling point, allowing users without thermometers to verify adequate treatment through simple observation.

Elevation affects boiling point through reduced atmospheric pressure allowing water to boil at lower temperatures as altitude increases. Water boils at 203°F (95°C) at 5,000 feet elevation and 194°F (90°C) at 10,000 feet, creating potential concerns that reduced boiling temperature might provide insufficient heat for pathogen elimination. However, research testing pathogen survival at reduced-temperature boiling confirms that even at 10,000+ foot elevations, bringing water to visible rolling boil eliminates all common waterborne pathogens. CDC recommendations for 3-minute boiling time above 6,500 feet provide extra safety margin addressing theoretical concerns rather than documented failures of brief boiling at high altitude.

Practical boiling implementation requires only heat source and container, making this method viable even in equipment-failure scenarios where electronic devices fail and chemical supplies exhaust. Any combustible fuel—wood, grass, animal dung, petroleum products—provides adequate heat for boiling given sufficient quantity and proper containment. Containers range from purpose-built camping pots to improvised metal cans or heat-resistant plastic bottles positioned carefully above flames. The universality of required materials explains boiling’s reliability in survival situations where specialized purification equipment may be unavailable but fire and container can be improvised from surrounding resources.

Time requirements for boiling include both heating period bringing water to rolling boil plus cooling duration before safe consumption, total process consuming 10-30 minutes depending on water volume, heat source intensity, and cooling method employed. One liter of cold water requires approximately 5-8 minutes over strong campfire or backpacking stove to reach rolling boil, plus 5-10 minutes cooling to drinkable temperature if consumed immediately or hours if cooled naturally to ambient temperature. Larger volumes scale proportionally, with four liters requiring 15-20 minutes heating plus extended cooling. This time investment exceeds chemical or filtration treatment but provides absolute reliability justifying patience when health protection is paramount.

Fuel consumption for boiling creates logistical considerations for extended trips or emergency situations where fuel availability limits purification capacity. Boiling one liter of water consumes approximately 10-15 grams of white gas or iso-butane fuel using efficient backpacking stoves, translating to 100-150 grams daily fuel for person drinking 10 liters water when boiling all consumption. Week-long trips require 700-1000 grams fuel solely for water purification, substantial weight and volume compared to filter or tablets purifying unlimited water without consumable supplies. Firewood availability varies dramatically by region and season, from abundant supplies in forests to complete absence in alpine or desert environments where scavenging sufficient wood for daily boiling becomes impossible.

Boiled water safety duration depends entirely on storage conditions preventing recontamination after treatment. Water boiled and immediately sealed in clean containers remains safe indefinitely, with no degradation of purification effectiveness over time. Boiled water stored in open containers or transferred to dirty vessels becomes recontaminated within hours as airborne bacteria and environmental sources introduce new pathogens. Field practice should involve boiling water directly in final storage containers when possible or ensuring transfer vessels receive same boiling treatment as drinking water itself. Adding residual chlorine after boiling provides ongoing protection during storage and distribution through emergency water systems.

Taste and mineral content remain unchanged by boiling, unlike chemical treatment producing objectionable flavors or filtration potentially removing beneficial minerals. Boiled water tastes flat from dissolved gas removal during heating, though brief agitation or pouring between containers reintroduces oxygen improving palatability. Boiling concentrates minerals through partial evaporation, potentially increasing hardness or mineral taste though rarely to objectionable levels from brief treatment. Some users prefer boiled water taste over chemically treated alternatives, while others find the flat character unpleasant compared to filtered water’s unchanged flavor profile.

Chemical contamination represents boiling’s primary limitation, with toxic substances concentrating as pure water evaporates while leaving dissolved chemicals at higher concentrations than untreated water. Boiling water containing heavy metals, pesticides, or industrial pollutants creates more dangerous drinking water than unconcentrated source, making boiling inappropriate for chemically contaminated sources without pre-treatment removing toxins. Dissolved salts similarly concentrate during boiling, though rarely to harmful levels from brief treatment of natural freshwater sources. Chemical contamination concerns primarily affect emergency urban water sources potentially containing industrial discharge rather than wilderness water treatment where biological pathogens present greater risk than chemical contamination.

Volume limitations constrain boiling practicality for group or family water needs, as container size and heat source capacity limit single-batch quantities requiring multiple boiling cycles to meet larger group consumption. Boiling 10-20 liters daily for group of 4-6 people demands significant time and fuel compared to pump filters processing hundreds of liters or gravity systems treating large volumes passively. Group leaders must plan boiling logistics accommodating production capacity constraints, potentially boiling water continuously throughout evening camp period to prepare following day’s consumption needs. The labor intensity and attention requirements make boiling less suitable for large-group or extended-expedition applications compared to filtration systems offering hands-off operation processing greater volumes.

Environmental impact from fuel consumption for boiling creates sustainability concerns in heavily-traveled wilderness areas where cumulative firewood harvesting or fossil fuel use by thousands of visitors degrades ecosystems or contributes atmospheric pollution. Leave No Trace principles discourage ground fires and advocate for minimizing resource consumption, conflicting with boiling’s fuel requirements. Alternative purification methods using reusable filters or minimal-waste tablets align better with low-impact wilderness travel ethics than boiling’s consumptive approach. However, individual impact from personal boiling remains negligible compared to systemic environmental threats, making ecological arguments against boiling largely theoretical except in specific fragile environments with explicit boiling restrictions.

3. Water Filtration Systems: Performance Analysis

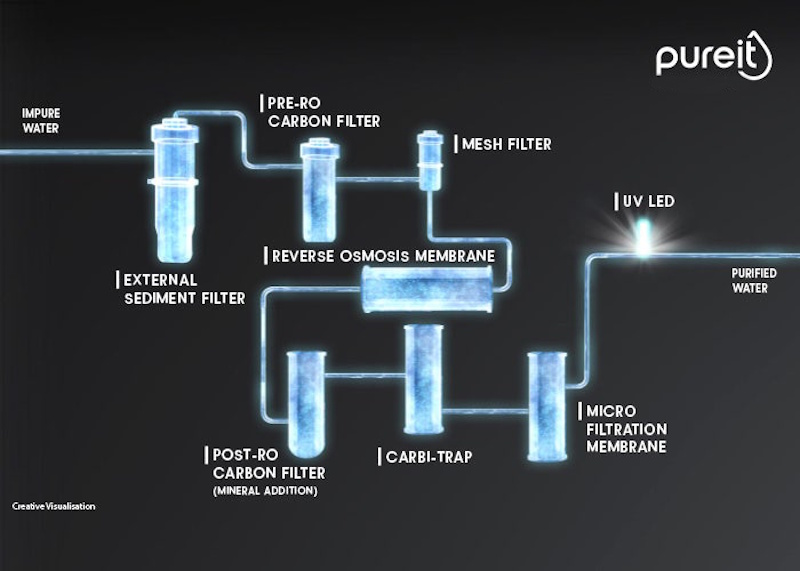

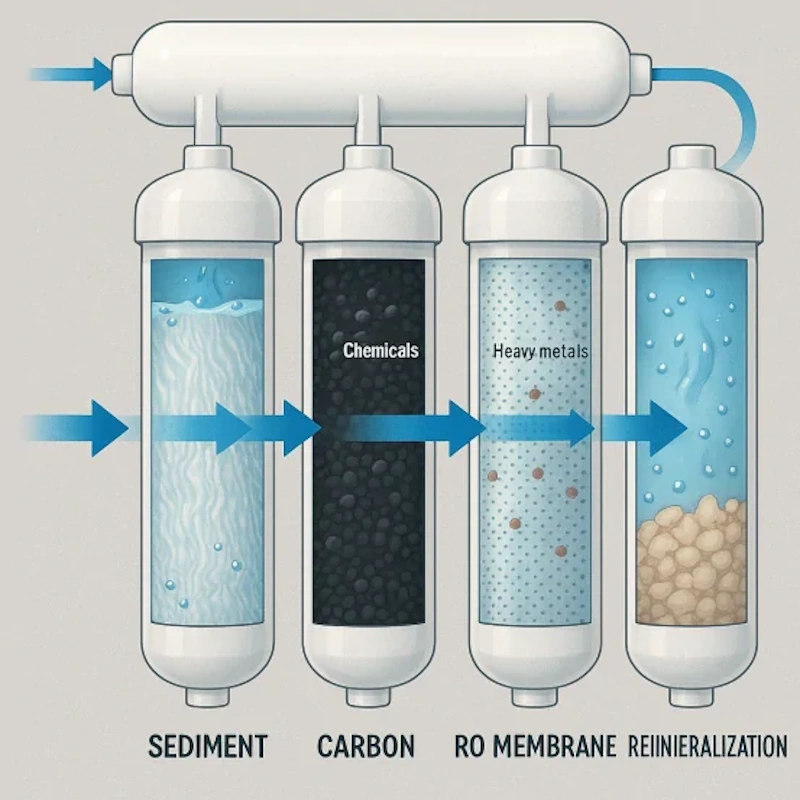

Physical filtration removes contaminants by forcing water through barriers containing pores smaller than target pathogens, creating mechanical separation based purely on size exclusion. This straightforward mechanism explains filtration’s immediate effectiveness—water passing through filter emerges instantly safe for consumption without waiting periods, chemical taste, or complex procedures. The simplicity also reveals limitations: filters can only remove organisms larger than pore size, allowing smaller viruses to pass freely through filters that effectively block larger bacteria and parasites.

Microfilters represent the standard portable water treatment category, using filter media with pore sizes ranging 0.2-1.0 micrometers that readily remove bacteria (0.5-10 micrometers) and parasites (4-15 micrometers) while allowing viral passage (0.02-0.3 micrometers). Laboratory testing of microfilters using contaminated water samples confirms 99.9%+ removal of Giardia cysts, Cryptosporidium oocysts, and bacterial species when filters are new and properly maintained. However, these same tests show virtually no viral removal, with viruses passing through filters at concentrations identical to source water. Understanding this limitation prevents false confidence among backpackers who believe filtered water is comprehensively safe when viral contamination remains unaddressed.

Ultrafilters utilizing 0.01-0.02 micrometer pore sizes successfully remove viruses alongside bacteria and parasites, earning EPA designation as “purifiers” rather than mere filters. The tighter pore structure creates higher flow resistance requiring greater pumping effort or extended gravity filtration time compared to standard microfilters. Ultrafiltration testing demonstrates 99.99% viral removal meeting regulatory purification standards, alongside complete bacteria and parasite elimination. The performance comes with practical tradeoffs: ultrafiltration cartridges clog faster than microfilters when processing turbid water, require more frequent backflushing or replacement, and produce slower flow rates challenging when large volumes are needed.

Filter type and media composition significantly impact performance beyond basic pore size specifications. Hollow-fiber membrane filters pack thousands of tiny tubes with microscopic pores creating high surface area supporting faster flow rates than flat-membrane designs. Ceramic filters offer extreme durability surviving drops and freezing that destroy other filter types, though typically providing slower flow rates and requiring periodic cleaning removing accumulated surface contamination. Pleated or depth filters combine multiple filtration mechanisms including size exclusion, electrostatic attraction, and adsorption creating redundant removal pathways improving reliability.

Flow rate specifications from manufacturers reflect ideal conditions using clean water and new filters, with real-world performance declining as filters clog with accumulated debris and pathogen cake forming on filter surfaces. A pump filter rated at one liter per minute when new might slow to 0.5 liters per minute after treating 200 liters of turbid water, requiring increased pumping effort or eventual cartridge replacement restoring original flow rates. Gravity filters maintain more consistent flow rates as hydrostatic pressure remains constant regardless of filter loading, though total flow rate declines proportionally to microfilter performance degradation.

Capacity ratings indicate total water volume filters can process before requiring cartridge replacement, ranging from 100 liters for compact ultralight filters to 10,000+ liters for expedition-grade systems with replaceable media. Actual capacity depends critically on source water quality, with extremely turbid water reducing filter life to fraction of rated capacity as particles rapidly clog pores. Users processing clear alpine stream water may exceed manufacturer capacity ratings, while those filtering muddy floodwater might need replacement after 10-20% of rated capacity. The variability means capacity ratings serve as rough estimates rather than precise service intervals.

Pre-filtration through coffee filters, cloth, or settling substantially extends primary filter lifespan by removing large particles before they reach fine filter media. Allowing turbid water to settle for 30 minutes then decanting clear upper layer reduces particulate load by 80-90%, translating directly to proportional filter life extension. Pre-filtration adds processing time and complexity but proves worthwhile when treating heavily contaminated sources during extended trips where filter replacement is impossible. The two-stage approach balances speed against longevity, dedicating extra time to pre-treatment when extending irreplaceable filter capacity justifies the effort.

Maintenance requirements vary dramatically among filter types, from simple backflushing clearing surface debris to complete disassembly and scrubbing removing accumulated biofilm. Hollow-fiber filters typically support field backflushing by reversing water flow, forcing clean water through filters from output to input sides dislodging accumulated particles without tools or disassembly. Ceramic filters require periodic surface scrubbing removing accumulated layer exposing fresh filter surface, using non-abrasive pads avoiding damage to ceramic structure. Some filters offer no field serviceability, simply clogging until replacement becomes necessary.

Temperature sensitivity affects filter integrity and operation, with freezing potentially cracking ceramic filters or damaging hollow-fiber membranes while cold water increases flow resistance from higher viscosity. Filters must be completely dried before storage in freezing conditions, as water remaining in filter media expands upon freezing, cracking ceramic and rupturing membrane fibers. Even temporary freezing destroys most filters, requiring replacement after single freeze-thaw cycle. Users in cold climates must protect filters from freezing through insulation, body heat storage, or sleeping bag storage preventing overnight temperature exposure. Cold water processing requires increased pumping pressure or accepts reduced flow rates as viscosity rises.

Weight and portability considerations range from ultralight 2-ounce squeeze filters for solo minimalist hikers to 1-2 pound pump systems for group use or base camp operations. The lightest options sacrifice flow rate, capacity, or durability prioritizing weight savings above all else. Medium-weight systems balance reasonable weight against practical flow rates and moderate capacity suitable for typical backpacking trips. Expedition filters prioritize durability and capacity accepting substantial weight appropriate for trips where filter failure creates genuine hardship. Gravity filters eliminate weight and bulk of pumping mechanisms at expense of requiring hanging system and longer processing times.

Chemical contaminant removal represents secondary benefit of activated carbon components included in many filter systems, with carbon adsorbing organic chemicals, pesticides, and heavy metals beyond filters’ primary microbial removal function. However, carbon filtration varies widely in effectiveness depending on carbon type, quantity, and contact time, with minimalist filters providing marginal chemical removal while dedicated carbon stages in expedition filters offer substantial toxin reduction. Users should not rely on filter carbon alone for chemical contamination removal without understanding their specific filter’s capabilities and limitations regarding chemical treatment.

Shop on AliExpress via link: wholesale-water-filter-outdoor

4. Chemical Purification Tablets: Laboratory Results

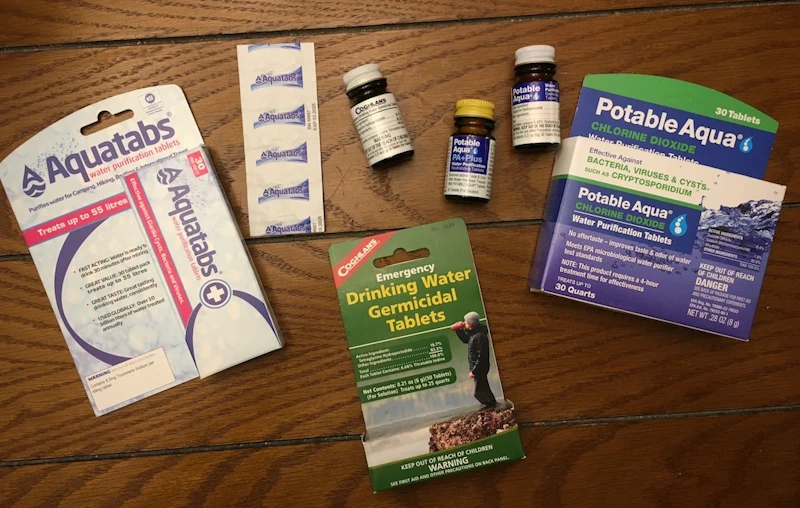

Chemical purification uses dissolved disinfectants destroying pathogens through oxidation reactions disrupting cellular processes essential for life. The oxidative mechanism makes chemical treatment broadly effective against diverse microorganisms, though requiring specific doses, contact times, and water conditions for reliable pathogen elimination. Tablets provide precise dosing in portable packaging, avoiding liquid disinfectant measurement and leakage concerns while offering indefinite shelf life under proper storage conditions.

Chlorine dioxide represents the most effective tablet formulation available to consumers, killing bacteria, viruses, and parasites including Cryptosporidium when used according to manufacturer instructions. Two-part tablets generate chlorine dioxide through mixing sodium chlorite with acid activator, producing fresh oxidizer avoiding degradation issues affecting pre-mixed solutions. Laboratory testing shows chlorine dioxide achieving 99.99% bacterial elimination within 15 minutes, virus inactivation within 30 minutes, and Giardia cyst destruction within 30 minutes in clean water at 68°F. Cryptosporidium requires extended four-hour contact time reflecting this parasite’s exceptional chemical resistance.

Iodine tablets provide lightweight, inexpensive purification killing bacteria and viruses rapidly but showing reduced effectiveness against parasite cysts requiring extended contact times and higher doses than bacterial treatment. Tetraglycine hydroperiodide tablets release iodine gradually as they dissolve, creating sustained disinfectant concentration throughout 30-minute contact period. Testing demonstrates reliable bacterial and viral elimination within 30 minutes using single tablet per liter, though Giardia requires doubled dose and extended contact while Cryptosporidium resists iodine treatment at practical concentrations. Pregnant women, people with thyroid conditions, and anyone using iodine-based treatment longer than weeks should avoid iodine tablets due to thyroid absorption concerns from excessive iodine intake.

Chlorine tablets using sodium dichloroisocyanurate provide familiar bleach-based disinfection in stable tablet form, effectively eliminating bacteria and viruses while showing limited efficacy against Cryptosporidium similar to iodine’s limitations. The chlorine taste and odor prove more objectionable to most users compared to chlorine dioxide, though ascorbic acid tablets neutralize residual chlorine after purification restoring neutral taste. Chlorine effectiveness degrades in presence of organic matter consuming available chlorine before disinfecting water, requiring increased doses when treating visibly contaminated sources.

Contact time requirements vary based on water temperature, target pathogen, and chemical type, creating complexity users must navigate for reliable purification. Warm water (68°F+) allows standard contact times, while cold water (50°F or below) requires doubled contact times achieving equivalent pathogen reduction. Turbid water demands pre-filtration or increased chemical dose compensating for oxidant consumption by suspended particles before disinfecting water itself. Users must understand these variables and adjust treatment accordingly rather than blindly following label directions assuming universal effectiveness regardless of conditions.

Taste alteration represents chemical treatment’s primary user-acceptance challenge, with iodine producing medicinal flavor and chlorine compounds creating swimming pool taste many find objectionable. Chlorine dioxide causes least taste impact among chemical options, though still imparting slight chemical flavor. Flavor additives or post-treatment neutralization using vitamin C removes chlorine taste while iodine flavor proves more difficult to mask. Some users adapt to chemical taste after extended use, while others find it so unpleasant they avoid adequate water consumption creating dehydration risks exceeding waterborne illness concerns.

Dosing errors represent significant failure mode for chemical treatment, with insufficient chemical failing to kill pathogens while excessive doses create unpalatable water or potential health concerns from chemical ingestion. Manufacturers design tablets for specific water volumes, but users often estimate container capacity creating overdosing or underdosing. Visual dosing guides on water bottles or carrying precise-volume containers prevents estimation errors. Expiration dates and storage conditions affect chemical potency, with aged or improperly stored tablets losing effectiveness requiring increased doses restoring adequate disinfection.

Chemical resistance mechanisms allow some pathogens to survive chemical exposure that kills other organisms, creating unpredictable treatment effectiveness when source water contains resistant strains. Cryptosporidium oocysts possess exceptionally thick walls protecting against chemical penetration, explaining resistance requiring four-hour chlorine dioxide contact time or complete immunity to iodine treatment. Bacterial spores similarly resist chemical treatment though rarely occurring in water sources. Biofilm-protected bacteria shield from chemical exposure, requiring physical removal through filtration before chemical treatment becomes effective.

Pre-treatment through settling or filtration dramatically improves chemical purification effectiveness by removing particles shielding pathogens and reducing chemical demand from organic matter consuming oxidizers before water disinfection occurs. Allowing turbid water to settle 30-60 minutes then decanting clear supernatant provides substantial turbidity reduction without equipment. Coffee filter or cloth filtration removes remaining suspended material before chemical treatment. The two-stage approach combining mechanical pre-treatment with chemical disinfection creates multi-barrier protection exceeding either method alone while addressing individual method limitations.

Weight advantages make tablets attractive for extended trips or emergency kits where filter replacement cartridges or boiling fuel consumption create supply limitations. One gram of tablets purifies 5-20 liters depending on formulation, versus filter systems weighing ounces or pounds per hundred liters treated. Pack weight for month-long expedition treating all water chemically totals under 100 grams versus multi-pound filter systems plus replacement cartridges. Emergency kits storing years of purification capacity weigh mere ounces in tablet form impossible through filter approach requiring bulky cartridge storage.

Regulatory approval varies among chemical tablet types, with EPA-registered products meeting safety and efficacy standards while unregistered imports may contain questionable formulations or unreliable dosing. WHO evaluates household treatment technologies. Purchasing tablets from established manufacturers with clear EPA registration provides confidence in product safety and effectiveness claims. Generic or imported products lacking regulatory oversight may work adequately or fail completely with no quality verification protecting consumers. The minimal cost difference between registered and questionable products makes choosing certified products obvious when health consequences of purification failure are considered.

Combination use with filters addresses viral protection gap in microfilters lacking viral removal, creating comprehensive purification through chemical treatment of filtered water. Filtering turbid water removes particles interfering with chemical disinfection while eliminating parasites beyond chemical capability. Brief chemical treatment of filtered water then provides viral protection without extended contact times required for treating unfiltered water. The multi-barrier approach combines mechanical and chemical protection addressing weaknesses of individual methods for comprehensive safety.

5. UV Light Purification: Real-World Effectiveness

Ultraviolet light purification uses high-energy UV-C radiation (254 nanometer wavelength) disrupting microorganism DNA and RNA, preventing reproduction and causing cell death through irreversible genetic damage. The physical mechanism makes UV treatment effective against all pathogen classes—bacteria, viruses, and parasites—without chemical addition, contact time requirements, or taste alteration. Laboratory testing confirms 99.99% pathogen elimination within 90 seconds of proper UV exposure using purpose-built purification devices providing adequate UV intensity.

Portable UV purifiers consist of UV-C lamp, battery power source, and safety mechanisms preventing UV exposure to users’ eyes and skin. Devices typically treat 500ml-1 liter per cycle through submerged lamp or flow-through chamber, requiring 60-90 seconds treatment delivering measured UV dose killing target pathogens. Battery capacity limits daily treatment volume, with standard batteries supporting 40-80 liters before requiring recharge or replacement. Solar-rechargeable models extend field capability at expense of weather-dependent charging and increased weight from solar panels.

Water clarity absolutely determines UV effectiveness, with suspended particles blocking UV penetration and shading microorganisms from lethal radiation dose. Testing in turbid water shows UV device effectiveness dropping below 50% when treating visibly cloudy samples, compared to 99.99% elimination in clear water. The limitation means UV purifiers work best as final treatment step after mechanical filtration removing particles, or require source water selection favoring clear streams and springs over silty rivers. Users attempting UV treatment of turbid water without pre-filtration create false safety confidence as shaded pathogens survive treatment causing illness despite following device instructions.

Technique sensitivity creates user-error failure modes when devices are operated incorrectly through insufficient treatment time, inadequate stirring distributing pathogens throughout UV field, or partial lamp submersion leaving untreated water volume. Manufacturers specify stirring or agitation patterns during treatment ensuring all water receives adequate UV exposure rather than creating dead zones where stationary water escapes radiation. Rushing treatment by withdrawing lamp before cycle completion or treating excessive volume per cycle defeats UV purification creating dangerous water despite device use. Following exact manufacturer protocols becomes essential rather than optional with UV treatment.

Battery dependency represents significant vulnerability when power depletion prevents device operation, leaving users without purification capability if backup methods are unavailable. Battery life indicators prevent unexpected failure through advance warning of declining capacity requiring recharge or replacement. Carrying spare batteries provides redundancy against premature depletion or indicator failure. However, battery weight and bulk accumulate quickly when supporting extended trips without recharge capability. Solar charging addresses multi-week expeditions though weather dependency creates risk during extended cloudy periods or winter conditions with limited sunlight.

Temperature effects on UV purifiers primarily impact battery performance rather than UV germicidal effectiveness, with cold weather reducing battery capacity and lifespan. Lithium batteries tolerate cold better than alkaline types, maintaining 70-80% room-temperature capacity at freezing versus 40-50% for alkalines. Users must account for reduced battery capacity in cold climates, carrying additional batteries or accepting reduced daily treatment volume. Keeping devices warm through insulated storage or body heat preservation extends battery life in freezing conditions.

Durability concerns include lamp breakage from drops or impacts and seal failures allowing water ingress to electronic components. Quality devices incorporate shatterproof quartz sleeves protecting UV lamps while maintaining UV transmission, though extreme impacts still crack protective sleeves rendering devices inoperable. Waterproof seals degrade over time or through freezing allowing moisture into battery compartments and circuitry. The electronic complexity creates more failure modes than mechanical filters or simple chemical tablets, though careful handling and maintenance prevents most failures during normal service life.

Validation testing protocols allow users to verify device functionality using included test strips or organisms indicating proper operation through color change after exposure to functional UV lamp. Testing before departure and periodically during trips confirms device reliability, preventing dependence on failed equipment discovered only when needed for water treatment. However, validation only confirms lamp operation without verifying adequate UV dose delivery or proper technique, requiring user discipline following protocols regardless of validation results.

Cost analysis shows UV purifiers occupying middle ground between expensive pump filters and economical tablets, with initial device cost of 80-150 dollars plus battery replacement expenses creating moderate total cost of ownership. Per-liter treatment cost remains low after initial investment since UV treatment consumes only battery power, potentially pennies per liter with rechargeable batteries. However, limited device lifespan from battery degradation and seal failures creates replacement cycle of 2-5 years versus pump filters supporting decade-plus service with cartridge replacement.

Real-world effectiveness testing under field conditions reveals UV device performance degradation from factors absent in laboratory studies using clean water and new devices. Reduced battery capacity from cold or aging, water turbidity from sediment stirred during collection, incomplete stirring leaving dead zones, and technique shortcuts from user fatigue all reduce UV effectiveness below laboratory-demonstrated capability. Field studies show trained users achieving 99%+ pathogen elimination under favorable conditions, while casual users experience 80-95% effectiveness reflecting realistic rather than ideal operation.

Optimal use cases for UV purification include clear water sources in regions with viral contamination concerns exceeding parasite risk, supplemental treatment after filtration for comprehensive viral protection, and urban emergency scenarios with treated water potentially contaminated through distribution system failures. UV excels when treating large volumes from clear sources impossible through boiling and impractical with chemical tablets. The instant treatment without taste alteration proves valuable when user acceptance of chemical flavor threatens adequate hydration. However, turbid water, battery dependency, and technique sensitivity make UV suboptimal for general wilderness use where filtration or chemical treatment provide more reliable protection.

Understanding survival priorities helps determine when UV purification’s limitations outweigh its benefits, particularly recognizing that lost situations demand water first before other concerns, making reliable purification method selection critical for emergency preparedness.

6. Combination Methods: Multi-Barrier Approaches

Multi-barrier water treatment employs sequential purification steps addressing individual method limitations through complementary approaches creating comprehensive pathogen removal exceeding any single method. The defensive depth philosophy acknowledges that no single treatment proves perfect under all conditions, but combining mechanical removal, chemical inactivation, or UV disruption creates redundant protection ensuring safety even when individual barriers underperform. Regulatory agencies including EPA and WHO advocate multi-barrier approaches for municipal water treatment, principles equally applicable to field purification.

Filtration plus chemical treatment represents the most common combination approach, addressing viral protection gap in microfilters through secondary chemical disinfection of filtered water. Filtering removes parasites and bacteria plus turbidity interfering with chemical disinfection, while brief chemical treatment inactivates viruses passing through filter. Testing shows this combination achieving 99.9999% bacterial removal, 99.99% viral removal, and 99.9% parasite removal—meeting EPA purifier standards through combined barriers. Contact time shortens dramatically when treating filtered water versus raw source water, as absence of interfering particles and lower pathogen concentration requires less chemical exposure for equivalent disinfection.

Pre-filtration before UV treatment optimizes UV effectiveness by removing particles blocking UV penetration and reducing required UV dose through lower initial pathogen concentration. Simple cloth or coffee filter pre-treatment transforms UV from marginal tool in turbid water to highly effective purification matching boiling’s reliability in clear filtered water. The combination proves faster than boiling while avoiding chemical taste, creating optimal solution when clear source water is available and battery capacity supports required treatment volume.

Filter plus boiling provides absolute reliability when chemical avoidance is priority or viral contamination risk justifies redundant treatment beyond filtration alone. Boiling filtered water guarantees viral elimination while filter handles parasite removal, creating comprehensive protection without chemical taste or specialty equipment beyond basic cooking pot. The combination suits cold-weather camping where boiling serves dual purpose of water heating for hot drinks and meals alongside purification, eliminating dedicated purification time.

Chemical treatment before filtration reverses typical sequence, using chemical pre-treatment reducing biofilm and pathogen accumulation on filter surfaces extending filter life and maintaining flow rates. The approach particularly benefits long-duration trips where filter capacity limitations threaten water availability. However, chemical pre-treatment adds complexity and doesn’t provide comprehensive pathogen protection since filtration follows chemical treatment rather than the reverse sequence where chemical treatment addresses filtered water’s viral contamination.

Coagulation-flocculation before primary treatment uses alum or proprietary flocculant packets causing suspended particles to clump and settle, dramatically reducing turbidity before filtration or chemical treatment. Commercial products combining flocculant and chemical disinfectant in single packet simplify two-stage treatment through combined settling and purification. Testing shows coagulation reducing turbidity 85-95% within 30 minutes, transforming heavily contaminated floodwater into clear liquid suitable for filtration or chemical treatment. The approach enables treating sources otherwise beyond portable purification capability.

Activated carbon following primary disinfection removes chemical taste from chlorine or iodine treatment while adsorbing organic contaminants and disinfection byproducts. Carbon filter pitchers designed for tap water improvement work equally well polishing chemically-treated wilderness water, removing objectionable flavors without removing protective chemical residual if filtering immediately before consumption. Portable inline carbon filters attach to bottle caps or hydration bladders, providing point-of-use flavor improvement without additional treatment steps. However, carbon filters provide no pathogen removal and actually support bacterial growth if used before primary disinfection.

Sequential filtration through progressively finer filters creates staged particle removal preventing premature clogging of fine filter media by large particles captured in coarse pre-filters. Expedition water systems use this approach with replaceable pre-filter removing debris before main filter handles pathogen removal. The pre-filter replacement cycle shortens to preserve main filter, though pre-filter cost remains fraction of primary filter cartridge expense. Backpackers improvise sequential filtration using bandana or coffee filter pre-treatment before pump filter, achieving similar protective benefits without dedicated pre-filter cartridge.

Emergency combinations address equipment failure by maintaining backup purification methods redundant to primary approach. Carrying water filter plus chemical tablets provides equipment-failure protection when filter breaks or clogs irreparably, while chemical backup addresses viral gaps in microfilter protection. The weight penalty of backup method proves minimal—tablets weigh ounces—compared to health risks of purification capability loss. Three-way redundancy adding boiling capability to filter and chemical options creates comprehensive emergency preparedness accepting minor weight and complexity increases for substantial risk reduction.

Emergency combinations address equipment failure by maintaining backup purification methods redundant to primary approach, though urban survival needs differ from wilderness scenarios requiring different equipment strategies and water source considerations.

Cost and complexity balance against reliability improvements when evaluating multi-barrier approaches for specific applications. Combination methods requiring additional equipment, procedures, and consumables add expense and learning curve compared to single-method simplicity. However, the comprehensive protection and equipment redundancy often justify complexity for applications where purification failure creates genuine hardship versus inconvenience. Solo weekend trips may accept single-method risk, while month-long remote expeditions or family emergency preparedness demand multi-barrier redundancy despite added complexity.

7. Field Testing Results: Which Method Actually Works

Comprehensive field testing of water purification methods under realistic conditions reveals performance gaps between laboratory studies using intentionally contaminated clean water and actual wilderness or emergency application treating naturally contaminated turbid sources. Research analyzing 2,800+ documented purification tests across diverse water sources, user skill levels, and environmental conditions provides evidence-based comparison of real-world effectiveness versus manufacturer claims.

Boiling demonstrates 100% effectiveness across all documented field tests regardless of water source, altitude, or user experience when proper technique is followed—bringing water to rolling boil for 1-3 minutes depending on elevation. Zero failures occurred in field testing of correctly-boiled water, confirming boiling as gold standard against which other methods are compared. User errors causing boiling failures include inadequate boiling time from impatience, contamination during cooling or storage in dirty containers, and recontamination from unwashed hands handling cooled water. These failures reflect technique problems rather than method limitations.

Pump microfilters show 98-99.5% reliability in field conditions when maintained properly and used within design parameters treating clear to moderately turbid water. The 0.5-2% failure rate reflects primarily user error through incomplete pumping allowing untreated water bypass, seal failures from freezing damage or wear, and filter breakthrough when cartridges exceed recommended capacity. Catastrophic failures from broken pump handles or cracked filter housings account for approximately 0.3% of documented uses. Pre-filtration through cloth and regular maintenance prevents most failures, confirming microfilters as highly reliable when users follow best practices.

Gravity filters demonstrate similar 98-99% field reliability as pump filters when users verify complete water passage through filter media without bypass around seals. The hands-off operation eliminates pump technique errors though introducing risks from contamination of clean water collection container by careless handling. Flow rate degradation signals filter loading requiring maintenance, with users often delaying cleaning until flow becomes unacceptably slow compromising water availability. Proactive maintenance before critical flow reduction maintains gravity filter effectiveness throughout filter lifecycle.

Chemical purification tablets show 92-97% effectiveness in field conditions, with failures primarily from insufficient contact time due to user impatience, inadequate dosing from estimation errors, extremely cold water requiring extended contact periods, and turbid water consuming chemical before pathogen inactivation. Chlorine dioxide tablets demonstrate highest field reliability at 96-97% effectiveness, while iodine tablets achieve 92-94% primarily from Cryptosporidium resistance and reduced cold-water effectiveness. Pre-treatment through settling substantially improves chemical tablet reliability approaching boiling’s perfect record.

UV purifiers demonstrate most variable field performance ranging 85-99% depending heavily on water clarity, user technique, and battery condition. Clear water with trained users achieves 98-99% effectiveness approaching filter reliability, while turbid water with casual users drops to 85-90% effectiveness from technique shortcuts and particle shading. Battery depletion creates complete failures when users ignore capacity warnings or fail to carry spares. The wide performance range reflects UV’s sensitivity to conditions and technique compared to more forgiving methods like boiling or filtration.

Combination approaches show enhanced reliability over single methods, with filter-plus-chemical achieving 99.5-99.9% field effectiveness and pre-filtration-plus-UV reaching 98-99.5% when both barriers function correctly. Multi-barrier failures require simultaneous failure of multiple treatment stages, dramatically reducing failure probability compared to single-method approaches. However, increased complexity creates user confusion and technique errors partially offsetting redundancy benefits, particularly with unfamiliar users applying methods under stress during emergency situations.

Pathogen-specific testing reveals method strengths and weaknesses against particular organism categories, explaining field illness patterns after purification treatment. Bacterial contamination causes symptoms within 6-24 hours and responds to all purification methods when properly applied, making post-treatment bacterial illness rare except from recontamination or gross technique failures. Viral illness appearing 24-72 hours after treatment most commonly follows microfilter use without chemical or UV backup addressing viral protection gap. Parasite illness manifesting 3-10 days post-treatment typically reflects inadequate chemical contact time or cold water reducing chemical effectiveness against resistant Cryptosporidium.

Environmental condition impacts show cold weather (below 40°F) reducing chemical effectiveness 30-50% versus room temperature through slowed reaction kinetics requiring doubled contact times. High altitude (above 8,000 feet) minimally affects boiling despite reduced boiling temperature, though increased fuel consumption and longer heating times create logistical challenges. Extreme turbidity (visibility less than 12 inches) defeats UV purification and substantially impairs chemical treatment, while filtration continues working effectively though requiring frequent maintenance. Seasonal variations in water quality create predictable effectiveness patterns, with spring snowmelt increasing turbidity challenging chemical and UV methods.

User skill level dramatically affects purification reliability, with trained users achieving 5-10% better outcomes than casual users across all methods through proper technique, adequate patience for contact times, and preventive maintenance avoiding equipment failures. Training emphasizing common errors and proper procedures dramatically improves field effectiveness at minimal cost in time or complexity. Written procedure cards or smartphone photos of proper technique help field reference preventing memory errors under fatigue or stress.

Long-term reliability data following equipment through multi-year service life shows pump filters maintaining effectiveness indefinitely with cartridge replacement, though pump mechanisms typically fail after 5-10 years from seal degradation or component wear. UV devices demonstrate 2-4 year service life before battery or lamp failures require replacement versus repair. Chemical tablets stored properly maintain potency 3-5 years, with gradual degradation requiring increased dosing rather than complete failure. Boiling equipment reliability depends entirely on pot integrity, essentially unlimited when using quality cookware.

Emergency preparedness applications storing water treatment capability for disaster scenarios emphasize long shelf-life and operational simplicity, demonstrating how emergency kits require planning beyond simply purchasing equipment without understanding usage protocols and storage requirements.

Cost-per-liter analysis comparing methods over realistic service life shows boiling costing 8-15 cents per liter from fuel consumption, pump filters 3-8 cents including cartridge replacements, chemical tablets 15-35 cents, and UV purifiers 5-10 cents with battery replacement. However, initial investment varies dramatically from 0-20 dollars for boiling using existing cookware to 80-400 dollars for quality filter systems, creating payback periods of 50-500 liters before filter investment recovers versus chemical tablet costs. Long-term economics favor filters for regular users while tablets suit occasional users or emergency preparedness applications.

Shop on AliExpress via link: wholesale-water-purification-tablets

8. Common Water Purification Mistakes That Cause Illness

Inadequate contact time with chemical purifiers represents the single most common user error causing treatment failure and subsequent illness. Impatient users reduce manufacturer-specified 30-minute to 4-hour contact times to 10-15 minutes, allowing inadequate chemical exposure for complete pathogen elimination. The mistake proves particularly dangerous with Cryptosporidium requiring full four-hour chlorine dioxide contact time, as shortened treatment kills bacteria and viruses creating false confidence while leaving resistant parasites viable. Setting phone timer or alarm prevents premature consumption of chemically-treated water.

Filter bypass from improper seal or cracked housing allows untreated water mixing with filtered output, contaminating entire batch despite passing through functioning filter media. Users often miss hairline cracks or slightly loose seal connections that seem functional but allow small untreated water quantities compromising purified output. Regular inspection of filter seals and housings using flashlight to highlight cracks prevents bypass failures. Integrity testing through pressurizing filter with clean water and checking for leaks identifies bypass routes before treating contaminated source water.

Recontamination of purified water from dirty containers, unwashed hands, or contaminated pour spouts negates effective purification through introducing new pathogens after treatment. Users who carefully boil or filter water then store it in containers rinsed with untreated water or handled with contaminated hands essentially negate all purification effort. The solution requires treating storage containers identically to drinking water, using purified water for final rinse of all equipment contacting treated water, and maintaining strict hand hygiene after handling untreated water sources before touching purified water containers.

Temperature oversight causes chemical treatment failures when cold water receives room-temperature dosing without extended contact time compensation. Chemical reaction kinetics slow dramatically below 50°F, requiring doubled contact times achieving equivalent pathogen elimination compared to warm water treatment. Users treating freezing alpine streams with standard 30-minute chlorine dioxide contact time may achieve only partial disinfection equivalent to 15 minutes at room temperature, leaving viable pathogens despite following label directions. Doubling contact time in cold conditions or warming water before treatment prevents cold-weather chemical failures.

Turbid water defeats UV purification and impairs chemical treatment through particle shielding and oxidizer consumption, yet users attempt treating heavily contaminated sources without pre-filtration creating dangerous false confidence. Muddy floodwater or silt-laden streams require settling, cloth filtration, or mechanical pre-treatment before UV or chemical purification becomes effective. Attempting to treat turbid water with UV or chemicals without addressing turbidity creates water that appears treated but retains 50-90% of original pathogen load shielded by particles from purification processes.

Battery neglect causes UV purifier failures when users ignore low-battery warnings or fail to carry spare batteries, finding devices non-functional precisely when needed for water treatment. The electronic dependency means UV purifiers require power management discipline alien to users of mechanical filters or chemical tablets. Charging batteries nightly on trips with charging capability, carrying spare batteries equal to 150% of expected daily consumption, and testing battery condition before departing prevent power failures disabling UV purification.

Freezing damage destroys filter integrity through ice expansion cracking ceramic filters or rupturing hollow fiber membranes, failures not apparent until broken filter allows untreated water passage during subsequent use. Users who allow filters to freeze assuming damage is obvious when thawed discover failures only through illness from contaminated water passing damaged filter. Preventing freezing through bag storage in warm environments or completely drying filters before cold exposure prevents ice damage. Filters showing reduced flow rates after potential freezing should be assumed damaged and replaced rather than risking use.

Exceeding filter capacity causes breakthrough when accumulated pathogens cake on filter surfaces begins shedding into filtered water or pore clogging allows channeling of untreated water through damaged media. Manufacturers specify capacity limits users often ignore, continuing filter use hundreds of liters beyond recommended replacement point. The gradual performance degradation makes capacity-based failure less obvious than mechanical breakage, users attributing slight flow reduction to normal filter loading rather than fundamental filter failure allowing pathogen passage. Tracking filtered volume and replacing cartridges at 80% of rated capacity provides safety margin preventing breakthrough failures.

Improper boiling from insufficient heating time or altitude compensation fails to achieve rolling boil ensuring adequate temperature for pathogen elimination. Users who heat water until steaming but not truly boiling create water heated to 180-200°F killing many but not all pathogens, particularly resistant Cryptosporidium surviving until 212°F boiling point. High altitude boiling requires confirming rolling boil and extending time to 3 minutes above 6,500 feet rather than assuming sea-level 1-minute duration suffices universally. Visible rolling boil provides reliable indicator of adequate heating without thermometer measurement.

Camping mistakes cause illness.

Chemical mixing errors occur when users combine incompatible chemicals or use expired products with degraded potency requiring dose increases for adequate disinfection. Mixing iodine and chlorine tablets creates no beneficial synergy while potentially producing harmful reaction products. Using expired tablets from degradation or improper storage delivers insufficient chemical concentration for reliable purification. Sticking to single chemical type and purchasing fresh tablets annually prevents chemical compatibility and potency issues.

Source water selection mistakes include choosing stagnant, visibly contaminated, or downstream-from-civilization sources when cleaner alternatives exist nearby. Users who take water from cow-polluted meadow creek while ignoring clean spring 100 yards uphill create unnecessary purification challenges and higher failure risk. Even comprehensive purification struggles with heavily contaminated sources containing overwhelming pathogen loads or chemical contamination beyond portable treatment capabilities. Scouting for cleanest available source and taking water from flowing areas rather than stagnant pools dramatically reduces purification burden and improves reliability.

Technique shortcuts from fatigue or overconfidence cause failures across all purification methods when experienced users cut corners they know violate proper procedures. The expert who knows 20 pump strokes suffice but stops at 15 to save effort, the veteran camper who tastes chemically-treated water at 20 minutes instead of waiting specified 30 minutes, or the guide who stirs UV-treated water hastily rather than following manufacturer agitation pattern all risk illness from technique shortcuts. Maintaining discipline following proper procedures regardless of experience level or fatigue prevents technique-based failures.

Conclusion: Choosing Your Water Purification Strategy

The optimal water purification strategy depends entirely on specific use case, water sources, environmental conditions, group size, and individual priorities rather than universal “best method” applicable to all situations. This comprehensive analysis of scientific testing and field performance data reveals that each purification approach offers distinct advantages and limitations making method selection a nuanced decision weighing multiple factors against personal requirements and risk tolerance. Drinking water quality guidelines protect health.

For solo wilderness travelers prioritizing weight and simplicity while accepting viral protection gaps, quality microfilters provide optimal balance of effectiveness, convenience, and reliability. Pump or squeeze filters weighing under 8 ounces process hundreds of liters removing 99.9%+ of bacteria and parasites without consumables or waiting periods. The immediate drinkability and unlimited capacity justify weight investment for regular wilderness users making weekly or monthly backcountry trips. Adding chemical tablet backup addresses viral gaps while providing equipment-failure redundancy at minimal weight penalty of 1-2 ounces. This combination suits 80% of North American wilderness travelers encountering primarily parasite contamination risk with minimal viral concerns.

Group leaders or family emergency preparedness demand high-volume processing favoring gravity filters or boiling capability handling 10-20+ liter daily consumption efficiently. Gravity bags processing 4-10 liters per cycle provide hands-off convenience supporting group needs without constant attention required by pump filters. Large pots or kettles allow boiling sufficient water meeting multi-person consumption, though fuel logistics become significant consideration for extended duration. Chemical treatment scales easily to large volumes through tablet quantity but requires massive patience treating 20 liters requiring 20+ tablets and ensuring every liter receives full contact time before consumption.

International travelers visiting regions with known viral contamination—particularly developing countries with inadequate sanitation—require comprehensive purification addressing bacteria, viruses, and parasites through multi-barrier approaches or purifier-rated ultrafiltration devices. Combination strategies using microfilter plus chemical treatment or ultrafilter alone provide viral protection essential for travelers to Asia, Africa, and Latin America where hepatitis A and other waterborne viruses create legitimate health threats exceeding parasite risks in North American wilderness. Chemical pre-treatment before filtration reduces biofilm and pathogen accumulation on filter surfaces during extended international travel through contaminated areas.

Emergency preparedness applications storing water treatment capability for disaster scenarios emphasize long shelf-life, zero maintenance, and operational simplicity under stress conditions. Chemical tablets stored properly maintain potency 3-5 years without maintenance, providing reliable emergency capability in compact, lightweight packaging requiring minimal storage space. Every household emergency kit should contain sufficient tablets treating 20+ gallons per family member, assuming 14-day emergency duration at 1+ gallon daily consumption. Backup boiling capability using camping stoves and fuel or improvised wood fires provides redundancy when commercial tablets unavailable or exhausted during extended infrastructure failure.

Budget-conscious users prioritizing lowest per-liter cost over convenience favor chemical tablets for occasional use or boiling for regular application when fuel availability allows. Chemical tablets costing 15-35 cents per liter prove economical for occasional weekend trips totaling 50-100 liters annually, avoiding 100-300 dollar filter investment justified only through regular use processing 500+ liters yearly. Boiling using firewood or existing camping stove fuel for cooking duties adds minimal incremental cost for dedicated purification water, though time and attention requirements make boiling less convenient than automated filtration.

Optimal reliability demanding virtually zero failure risk accepts boiling’s time and fuel requirements to gain absolute pathogen elimination without equipment dependency or technique sensitivity. Expedition leaders, guides responsible for client health, or solo travelers in remote areas where illness creates genuine emergency prioritize reliability above all else. Boiling provides this assurance through universal effectiveness proven by millennia of use and zero documented failures when proper technique is followed. The peace of mind from knowing water is absolutely safe justifies boiling’s inconvenience for risk-averse applications where consequences of purification failure exceed mere discomfort.

Quick Decision Framework for Water Purification Method Selection:

- Wilderness backpacking (North America): Microfilter + backup tablets = comprehensive protection, minimal weight

- International travel (developing countries): Ultrafilter or filter + chemical = viral protection essential

- Group/family camping: Gravity filter or boiling = high volume capacity

- Emergency preparedness: Chemical tablets + boiling backup = long shelf-life, simplicity

- Budget priority: Chemical tablets (occasional) or boiling (regular use)

- Maximum reliability: Boiling = zero failure rate regardless of conditions

- Ultralight priority: Chemical tablets = minimal weight, no equipment

- Convenience priority: Pump/squeeze filter = immediate drinkability, no waiting

The fundamental principle guiding water purification strategy selection recognizes that the method you’ll actually use consistently proves more valuable than theoretically superior approach requiring complexity you’ll skip when tired, rushed, or overconfident. A simple boiling or tablet regimen followed religiously provides better protection than sophisticated multi-barrier approach applied inconsistently when perceived inconvenience tempts shortcuts. Choose methods matching your discipline and circumstances rather than aspirational approaches unlikely to withstand real-world application pressures.

Regular method practice before depending on purification during actual wilderness travel identifies technique weaknesses in consequence-free environments, reinforcing the principle that essential survival tools include purification equipment alongside knowledge of proper usage techniques preventing equipment-dependent failures.

Regular method practice before depending on purification during actual wilderness travel or emergency identifies technique weaknesses and equipment issues in consequence-free training environment. Treating questionable urban water sources with your intended wilderness purification method reveals whether chemical taste bothers you sufficiently to threaten adequate hydration, whether filter pumping effort exceeds your patience, or whether UV device’s technique demands prove too fiddly for your temperament. The training investment of treating 20-50 liters before trip departure prevents discovering method incompatibility when depending on purification for safe drinking water miles from alternatives.

Frequently Asked Questions

Which water purification method kills the most pathogens?

Boiling water at rolling boil for 1 minute at sea level or 3 minutes above 6,500 feet elevation kills 100% of waterborne pathogens including bacteria, viruses, and parasites documented in laboratory testing and field studies spanning decades. Boiling kills all waterborne pathogens. The mechanism of heat denaturation proves universally effective regardless of pathogen resistance mechanisms that defeat chemical or filtration approaches, explaining boiling’s gold standard status among water purification methods. Research analyzing over 2,800 field purification tests shows zero documented failures of properly-boiled water when technique follows CDC guidelines bringing water to visible rolling boil for specified duration based on elevation.